OEM Supply Weighbridge Truck Scale - Unmanned intelligent truck weighbridge system – Wanggong

OEM Supply Weighbridge Truck Scale - Unmanned intelligent truck weighbridge system – Wanggong Detail:

Video

Features

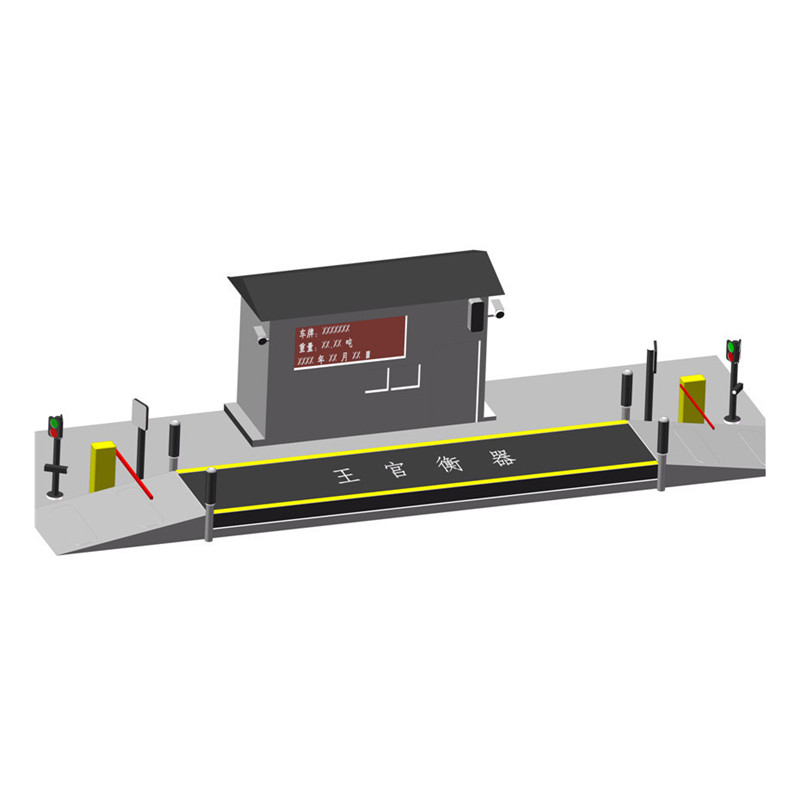

The new design of unmanned weighbridge system has changed the traditional manual operation weighing method, completed the unmanned, rapid, accurate and efficient weighing mode, and at the same time completed the sharing of data information and efficient management methods, which improved the development of the industry’s big data management capabilities and saved a large number of labor costs for the com

In the past, the traditional weighing s were complex and inconvenient, and it was not only very easy to record errors and omissions, but also to produce cheating. The unmanned weighbridge system really completes the automation technology and intelligent system of weighbridge weighing. In the unmanned mode, the automatic printing of weighing and weighing lists can be carried out without manual manipulation, which greatly saves the time of weighing the car.

Advantages

Overall, unmanned weighbridge systems have several advantages as below:

1. According to unmanned system, the completion of reducing 80% of the staff can save the enterprise a large amount of labor costs. At the same time, it also prevents the fraudulent personal behavior of drivers and employees, and prevents the loss of excess property of enterprises.

2. The unmanned weighbridge system is a detailed system that is easy to operate in practice. The previously overweight and complex procedural processes have been simplified. Only two or three people can be able to control the car to weigh reasonably, and the efficiency is further improved.

3. The anti-fraud system of the unmanned weighbridge system can reasonably avoid all kinds of fraudulent personal behaviors and reduce the risk. Prevent property damage to the enterprise

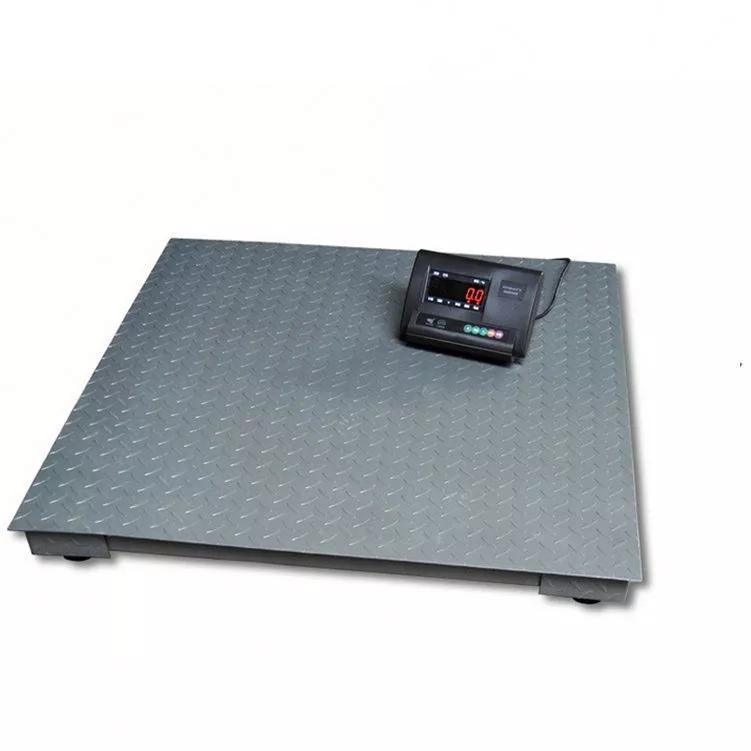

4.Weighing instruments and equipment can be compatible with 99% of the weighing instrument panel sockets, which is more convenient.

5. It is suitable for the connection of third-party intelligent management system, fully complete data information sharing, and complete the digital management of weighing.

Specification

| Specification Sheet of Truck Scale | |||||||

| Model | Capacity | Platform size | Division | Section | Load Cell | Weight (T) | 20FCL |

| SCS-60 | 60t-100t | 3x7m | 20kg | 2 | 6 | ±3.5 | 2 set |

| SCS-60 | 60t-100t | 3x8m | 20kg | 2 | 6 | ±4.0 | 2 set |

| SCS-60 | 60t-100t | 3x9m | 20kg | 2 | 6 | ±4.5 | 1 set |

| SCS-60 | 60t-100t | 3x10m | 20kg | 2 | 6 | ±5.0 | 1 set |

| SCS-80 | 80t-100t | 3x12m | 20kg | 3 | 8 | ±6.1 | 1 set |

| SCS-80 | 80t-100t | 3x14m | 20kg | 3 | 8 | ±7.0 | 1 set |

| SCS-80 | 80t-100t | 3x15m | 20kg | 3 | 8 | ±7.2 | 1 set |

| SCS-80 | 80t-100t | 3x16m | 20kg | 3 | 8 | ±8.0 | 1 set |

| SCS-80 | 80t-100t | 3x18m | 20kg | 4 | 10 | ±9.1 | 1 set |

| SCS-120 | 120t-150t | 3x16m | 50kg | 4 | 10 | ±8.3 | 1 set |

| SCS-120 | 120t-150t | 3x18m | 50kg | 4 | 10 | ±9.3 | 1 set |

Our unmanned weighbridge system advantages

1.It integrates the license plate recognition machine control, detector control, ultrasonic radar, microwave radar, traffic lights, barriers, card readers, capture, remote control, voice, LED screen as one control. Reduces the hassle of various devices and wiring. The corresponding integrated device can be controlled from the software to solve all problems with a single network cable.It is much easier installed and maintance by using this update new system.

2. Our new ultrasonic finisher uses the latest lidar to check the finishing of the vehicle tire to prevent the vehicle from pressing the edge, if there is a vehicle tire beyond the scale body, it can not be weighed. Card slot anti-cheating can be carried out to prevent the weight reduction caused by the vehicle not being fully weighed, or the weight becoming larger due to the rear car following the scale.

detail

Product detail pictures:

Related Product Guide:

Our commission is to serve our users and clients with best quality and competitive portable digital products for OEM Supply Weighbridge Truck Scale - Unmanned intelligent truck weighbridge system – Wanggong , The product will supply to all over the world, such as: United States, Slovenia, Atlanta, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat