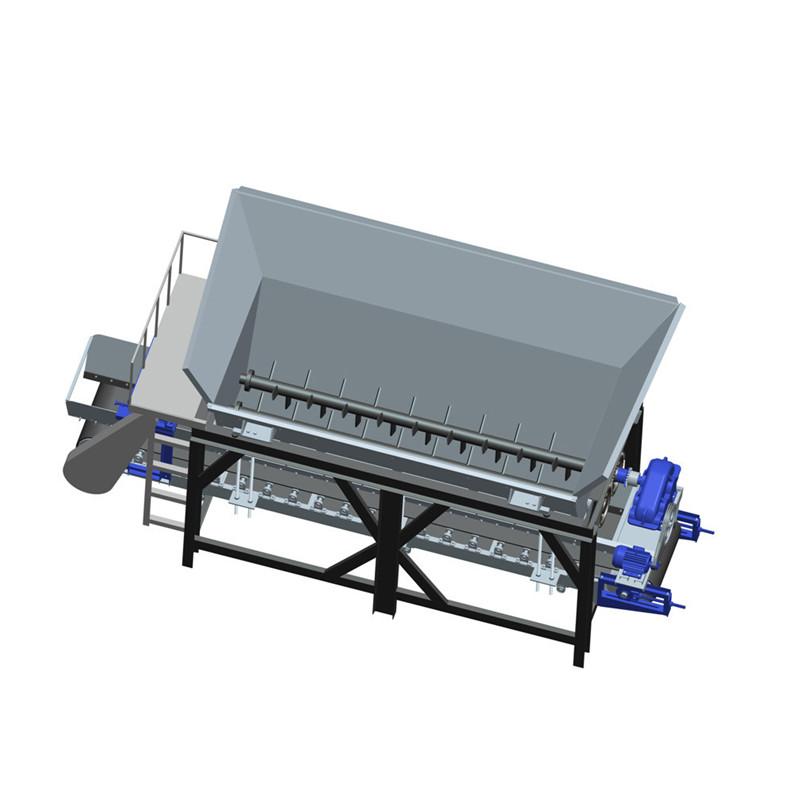

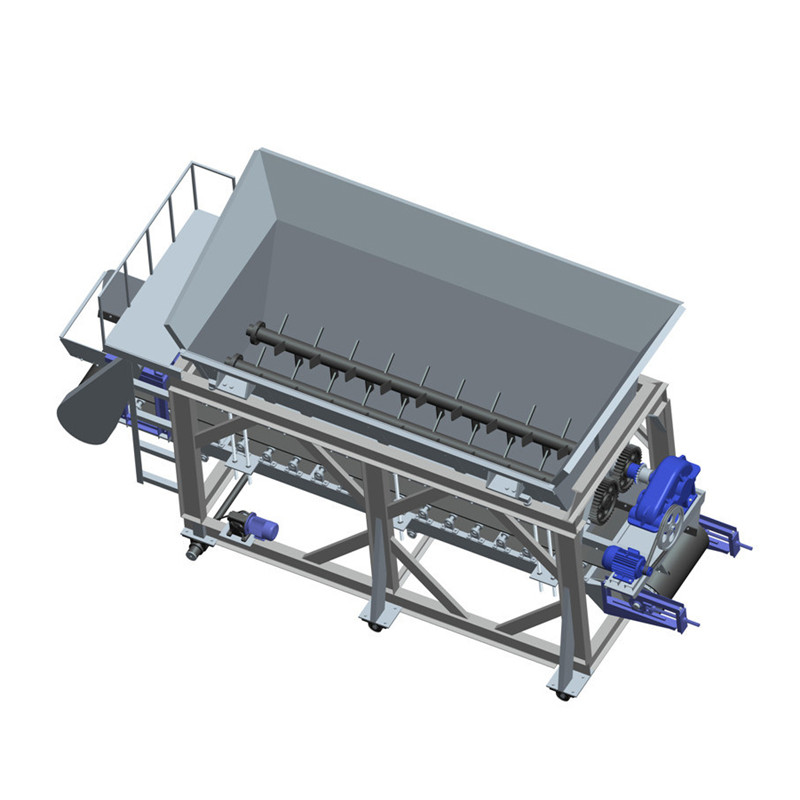

OEM Supply Batching Electronic Belt Scale Intelligent Automatic Measuring Equipment Conveyor Weigher

To create far more benefit for customers is our company philosophy; customer growing is our working chase for OEM Supply Batching Electronic Belt Scale Intelligent Automatic Measuring Equipment Conveyor Weigher, Our group members are goal to provides merchandise with significant performance cost ratio to our consumers, as well as target for all of us is usually to satisfy our consumers from all around the environment.

To create far more benefit for customers is our company philosophy; customer growing is our working chase for China Belt Scale and Ics, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we’ve been trying our best to be your good partner.

Video

Description

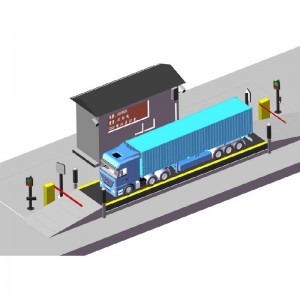

1. When the material needs to be loaded, the operator chooses to start the charging formula, and the LED screen displays the name of the material selected for the formula, the required weight, the installed weight, the corresponding ball mill number, the tolerance value, the installed weight, and the multi-layer warning light is green on, indicating that the charging can begin;

2. When the weight of the material reaches 90% of the required weight (can be set by itself), the yellow light of the multi-layer warning light is lit, reminding the loader driver to slow down;

3. When the weight of the material reaches the set weight of the material, the multi-layer warning light is red. Remind the loader that the loading should be stopped;

4. If the loading weight exceeds the set range, activate the sound and light warning headlights, prompt the administrator to carry out manual intervention processing, and can choose to reload or display the next material after manual treatment;

5. If the weight configuration is unqualified, the program will not carry out the next batching sequence, and the sound and light alarm until the personnel are processed;

6. When the electronic scaler weight stability value is obtained for 5 consecutive seconds (can be set by itself) within the tolerance value, the charging is qualified, and the system displays the next material, such as no next material, showing the loading completion.

Recipe result validation

When all the materials in the formula are weighed, the system will check and compare the weights of the materials in the formula one by one to see if the summary of the weighing meets the requirements, and after success, it is saved to the data.

Capacity Data

| All-electronic belt (mixing) feeder | 10t | 15t | 20t | 40t | 60t | 80t |

| Division | 5kg | 5kg | 10kg | 20kg | 20kg | 20kg |

| Max weighing | 10t | 15t | 20t | 40t | 60t | 80t |

| Mini weighing | 50kg | 50kg | 100kg | 200kg | 200kg | 200kg |

| Numbers of division | 2000n | 3000n | 2000n | 2000n | 3000n | 4000n |

| Conveying speed | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min |

| Total hopper feeding amount | 7 CBM | 10CBM | 14CBM | 28 CBM | 42 CBM | 56 CBM |

| Materials output | 100T | 100T | 100T | 100T | 100T | 100T |

| Steel materials | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 |

detail

To create far more benefit for customers is our company philosophy; customer growing is our working chase for OEM Supply Batching Electronic Belt Scale Intelligent Automatic Measuring Equipment Conveyor Weigher, Our group members are goal to provides merchandise with significant performance cost ratio to our consumers, as well as target for all of us is usually to satisfy our consumers from all around the environment.

To create far more benefit for customers is our company philosophy; customer growing is our working chase for OEM Supply Batching Electronic Belt Scale Intelligent Automatic Measuring Equipment Conveyor Weigher, Our group members are goal to provides merchandise with significant performance cost ratio to our consumers, as well as target for all of us is usually to satisfy our consumers from all around the environment.

OEM Supply China Belt Scale and Ics, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we’ve been trying our best to be your good partner.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat