Floor scales are an essential tool in various industries, including manufacturing, warehousing, and logistics. These heavy-duty scales are designed to accurately weigh heavy objects or materials. In this article, we will discuss how to install and use a floor scale effectively.

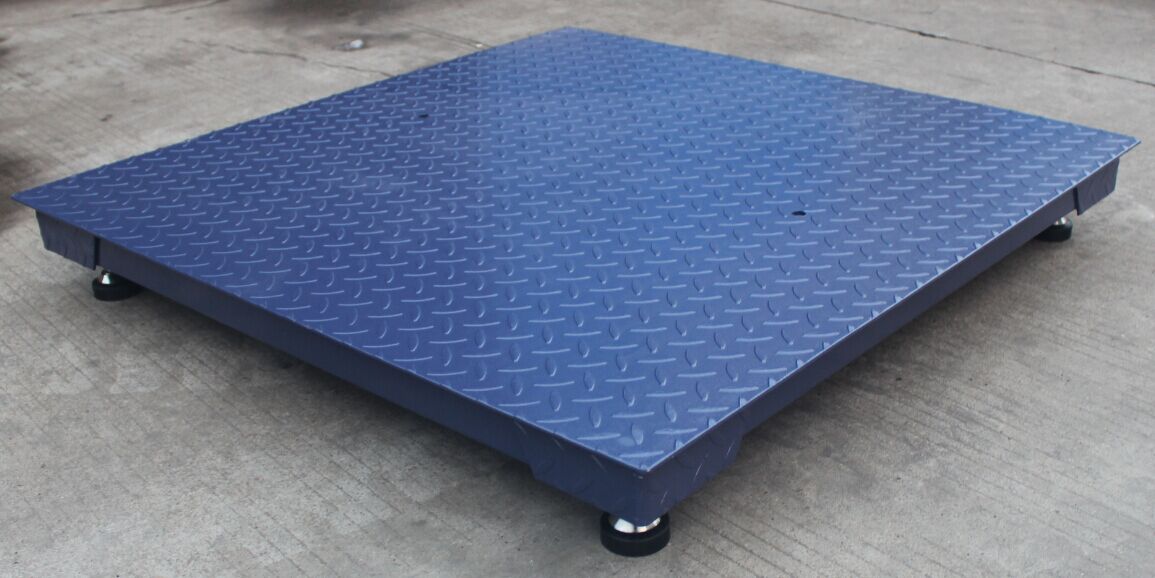

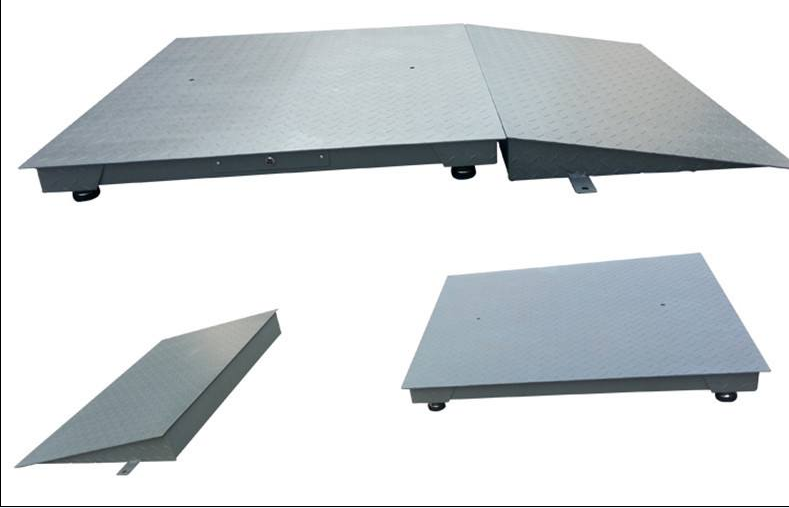

First and foremost, it is important to select the appropriate floor scale for your needs. Consider the weight capacity, size, and material of the scale. Floor scales come in various designs, including pit-mounted and surface-mounted options. Pit-mounted scales are recessed into the floor, ensuring a flush and seamless surface, while surface-mounted scales sit on top of the floor. Choose the type that best suits your requirements and available space.

Before installation, the floor surface should be prepared. Ensure that the surface is clean, flat, and level. Any debris or unevenness may affect the accuracy of the scale’s readings. It is recommended to sweep and mop the floor before installing the scale.

To install a floor scale, start by unpacking it and inspecting all the components. Refer to the manufacturer’s instructions for specific installation guidelines. Typically, floor scales are equipped with adjustable feet or leveling legs. Adjust these feet until the scale is perfectly level. Most scales have built-in bubble levels to assist with this process. Leveling the scale is crucial to ensure accurate weight readings.

Once the scale is leveled, secure it to the floor using anchor bolts or screws, as provided by the manufacturer. This step is essential to prevent the scale from shifting or moving during use. Make sure the scale is securely fastened to maintain its stability and accuracy.

After installing the scale, it is important to calibrate it. Calibration ensures that the scale is accurately measuring weights within its specified range. Consult the manufacturer’s instructions for calibration procedures, as they may vary depending on the model. Calibration usually involves placing known weights on the scale and adjusting its settings accordingly.

Now that the scale is properly installed and calibrated, it’s time to learn how to use it effectively. Start by turning on the scale and allowing it to stabilize. Ensure that there is no weight on the scale before turning it on to ensure an accurate reading. Some scales have a tare function that allows you to reset the scale to zero before placing an object on it. This feature is particularly useful when weighing items in containers or when subtracting the weight of packaging materials.

To use the scale, simply place the object or materials to be weighed on the scale’s platform. Make sure the weight is evenly distributed to ensure accurate readings. Wait for the reading to stabilize before recording the weight. Some scales have a digital display, while others may have a dial or pointer. Take note of the weight and remove the object from the scale.

Regular maintenance is essential to keep your floor scale in optimal condition. Clean the scale regularly to remove any dirt or debris that may affect its performance. Inspect the scale for any signs of damage, such as cracked or worn-out parts, and replace them if necessary. It is also important to periodically recalibrate the scale to ensure accurate readings.

In conclusion, installing and using a floor scale requires careful consideration and attention to detail. Proper installation, calibration, and maintenance are crucial to ensure accurate weight measurements. Follow the manufacturer’s instructions and guidelines to make the most of your floor scale and improve efficiency in your business operations.

Post time: Jun-29-2023