The Unmanned weighbridge system adopts an intelligent identification system, and its weighing process is automatically completed by a computer. It is equipped with a video monitoring system, which can prevent human intervention, prevent cheating, and improve weighing speed. It is an effective means for enterprises to strengthen measurement management. Today, we are offering you a brief introduction to the Unmanned weighbridge systems.

The Unmanned Weighbridge System is an intelligent weighing control system integrating automatic weighing of the truck scale, networked weighing of multiple weighbridges, anti-cheating weighing of the truck scale, remote weighing, and remote monitoring. The unattended weighbridge system is an enterprise material an effective measure to prevent cheating, which can effectively eliminate human errors and cheating loopholes in the measurement of enterprise materials

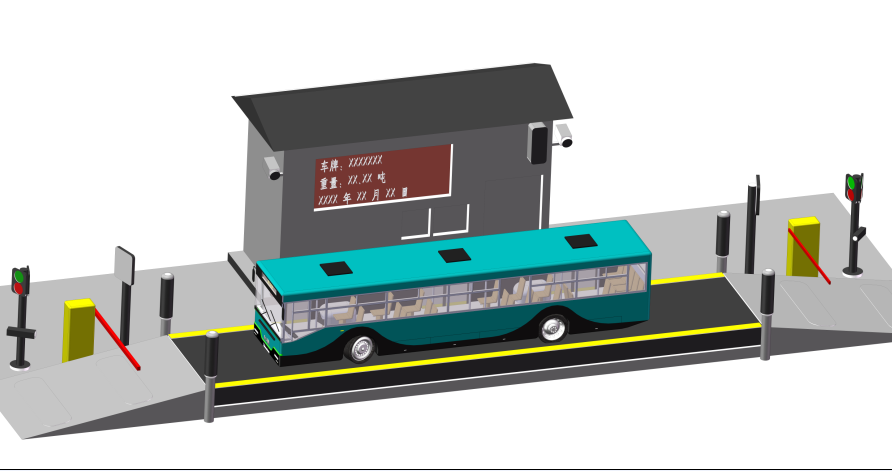

Unmanned weighbridge system consists of the following components: one-way/two-way automatic weighing software 1 set, 1 control box, 1 acquisition card (optional), 1 pair of speakers, 1 computer, 1 printer Taiwan (optional), 1 set of barrier gates (optional, including vehicle inspection and ground sensing), 2 pairs of infrared light curtains, 1 card reader (RF card and ID card), 1 traffic light (optional), electronic display Composed of 1 card and so on.

As far as the current development of the industry is concerned, unmanned weighbridge systems are based on the integration of weighing technology, computer, microelectronics, and network technology, can effectively prevent cheating, etc., and realize unattended intelligent management. It is a new generation of high-tech products that adapt to the development of today’s society. The unattended truck scale system is also widely used in steel, coal mine, chemical industry, garbage plant, thermal power plant and other industries, and has received many praises.

Post time: Mar-27-2023