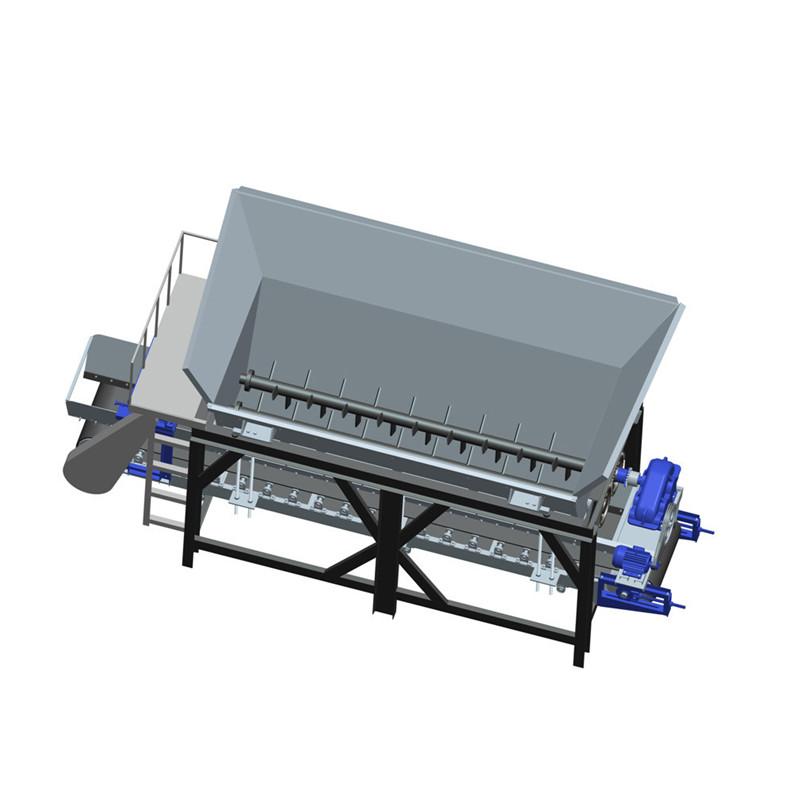

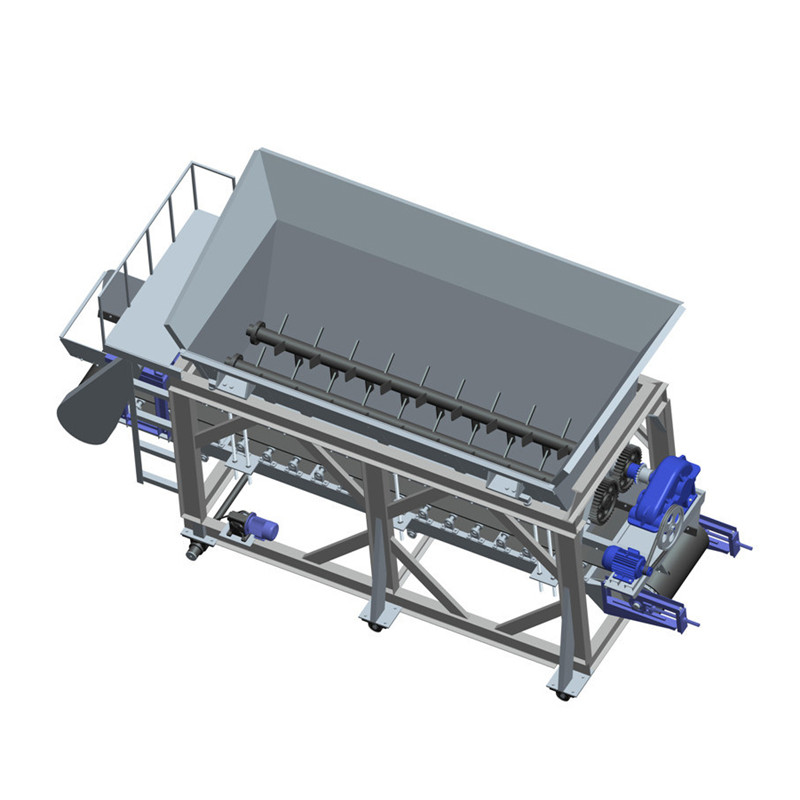

Automatic Hopper Weighing Feeding Scale for Bulk Materials

Video

Description of the Hopper Feeding Scale

Introducing the innovative hopper feeding scale, the latest addition to our product line!

Our hopper feeding scale has been designed with precision and efficiency in mind, specifically for industries such as agriculture, food production, and chemical processing. The scale is capable of accurately weighing and dispensing various types of materials, ranging from powders and granules to seeds and liquids.

One of the key features of our hopper feeding scale is its large hopper capacity, which enables users to input a large quantity of material at once, reducing the need for frequent refilling and improving overall workflow efficiency. The hopper is designed to be dust-proof, ensuring that the material being weighed remains clean and hygienic throughout the process.

Accurate and reliable weighing is essential in many industries, and our hopper feeding scale delivers just that. It is equipped with high-precision load cells, allowing for accurate readings even with materials of varying densities. The scale's tolerance level is adjustable, making it suitable for use with materials with different densities or flow characteristics.

In addition to its accuracy, our hopper feeding scale is also user-friendly and easy to operate. It comes equipped with a user-friendly control panel and an intuitive interface that allows users to manage the scale's settings and functions with ease. The scale features automatic material discharge, eliminating the need for manual intervention and streamlining the weighing process.

Furthermore, our hopper feeding scale is designed with durability and longevity in mind. It is crafted from high-quality materials, ensuring that it can withstand frequent use and exposure to harsh conditions. The scale also features an advanced anti-corrosion coating, which protects against moisture and corrosion damage, ensuring a longer lifespan.

The hopper feeding scale's versatility makes it ideal for use in a wide range of industries, including mining, chemical, and pharmaceutical industries, among others. It can be tailored to suit specific application requirements, and it is capable of handling both small and large-scale production operations.

The hopper feeding scale comes with dedicated customer support, a comprehensive user manual, and training materials, ensuring that all users can take full advantage of its capabilities.

Our hopper feeding scale is an innovative and reliable solution designed for the weighing and dispensing of a wide range of materials. Its accuracy, durability, and ease-of-use make it an ideal addition to any production process, improving efficiency, and reducing costs. Contact us today to learn more about how our product can transform your operations!

Description

1. When the material needs to be loaded, the operator chooses to start the charging formula, and the LED screen displays the name of the material selected for the formula, the required weight, the installed weight, the corresponding ball mill number, the tolerance value, the installed weight, and the multi-layer warning light is green on, indicating that the charging can begin;

2. When the weight of the material reaches 90% of the required weight (can be set by itself), the yellow light of the multi-layer warning light is lit, reminding the loader driver to slow down;

3. When the weight of the material reaches the set weight of the material, the multi-layer warning light is red. Remind the loader that the loading should be stopped;

4. If the loading weight exceeds the set range, activate the sound and light warning headlights, prompt the administrator to carry out manual intervention processing, and can choose to reload or display the next material after manual treatment;

5. If the weight configuration is unqualified, the program will not carry out the next batching sequence, and the sound and light alarm until the personnel are processed;

6. When the electronic scaler weight stability value is obtained for 5 consecutive seconds (can be set by itself) within the tolerance value, the charging is qualified, and the system displays the next material, such as no next material, showing the loading completion.

Recipe result validation

When all the materials in the formula are weighed, the system will check and compare the weights of the materials in the formula one by one to see if the summary of the weighing meets the requirements, and after success, it is saved to the data.

Capacity Data

| All-electronic belt (mixing) feeder | 10t | 15t | 20t | 40t | 60t | 80t |

| Division | 5kg | 5kg | 10kg | 20kg | 20kg | 20kg |

| Max weighing | 10t | 15t | 20t | 40t | 60t | 80t |

| Mini weighing | 50kg | 50kg | 100kg | 200kg | 200kg | 200kg |

| Numbers of division | 2000n | 3000n | 2000n | 2000n | 3000n | 4000n |

| Conveying speed | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min | 7.8m/min |

| Total hopper feeding amount | 7 CBM | 10CBM | 14CBM | 28 CBM | 42 CBM | 56 CBM |

| Materials output | 100T | 100T | 100T | 100T | 100T | 100T |

| Steel materials | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 |

detail

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat